Enzyme Dewatering

Enzyme Dewatering is a new citrus technology; it's based on a novel use of a specific enzyme activity. Process applies to citrus peels after juice and/or other by-products recovery, even involving the use of water and gives as result a dramatic decrease of peels humidity making them immediately suitable to be fed into dryers without the use of lime. Presses are always needed but NOT lime. CITRECH has studied this application together to important enzyme manufacturers and exerted a decisive role in the choice of enzyme activities and, especially, in the operative applications of this technology and played a key role in solving the main problem: how to capillary and homogenously apply an enzyme treatment to a solid waste without imparting further moisture. We emphasize that, like traditional lime treatment, this new application produces a further yield on the fruit of about 20 % but while in the lime case the alkaline liquid (press liquor) is a problem and can be managed just through a Waste-Heat Evaporator, with CITRECH Enzyme Dewatering technology this liquid is fully food-grade and can be used alone or together other citrus products

We want to stress out that liquid arising from our Enzymatic Dewatering have a pretty low water-soluble pectin content; this application can, hence, award eco-compatibility generating added value from a waste and helping to keep economic the overall fruit processing.

System performaces depend from fruit, enzyme dosage and holding time. Data below are average data for Naveline Oranges:

Weight of peels Vs fruit: 55 %

Weight of press cake Vs fruit: 34,1 %

Relative Humidity of peels BEFORE Enzyme Dewatering: 84,1 %

Relative Humidity of peels AFTER Enzyme Dewatering : 77,1 %

Weight of Liquid Vs peels after juice recovery: 33 %

Average Brix Degree of Liquid: 8,7 (76,7 % Vs Juice Brix Degree)

Average suspended solids content into Liquid: 8 %

Average Water Soluble Pectin content of Liquid (mg/l): 350 (at 8,7°Bx)

Weight of press cake Vs fruit: 34,1 %

Relative Humidity of peels BEFORE Enzyme Dewatering: 84,1 %

Relative Humidity of peels AFTER Enzyme Dewatering : 77,1 %

Weight of Liquid Vs peels after juice recovery: 33 %

Average Brix Degree of Liquid: 8,7 (76,7 % Vs Juice Brix Degree)

Average suspended solids content into Liquid: 8 %

Average Water Soluble Pectin content of Liquid (mg/l): 350 (at 8,7°Bx)

The same tecnique on ripe Valencia oranges gave a Brix Degree of Liquid of 11,3 and the liquid was representing 40 % (w/w) of peels after juice winning. Relative Humidity of press cake was ranging between 75 and 77 %.

It is important to point out that above data refer to a plant in which contact time between peels and enzyme is very limited; increasing contatat time it's possible to obtain peels with a relative humidity close to what obtainable in the traditional lime process.

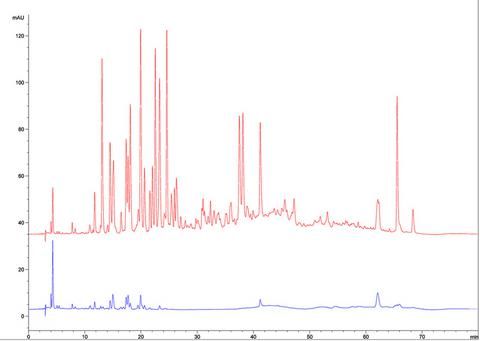

Liquid coming from Enzyme Dewatering has just a little cloudiness and contains high quantities of flavonoids; Citrech recommends debittering on absorber resins for an optimal use. Hereinafter howliquid looks like before and after debittering and HPLC chromatograms of flavonoids before and after treatment:

Liquid coming from Enzyme Dewatering has just a little cloudiness and contains high quantities of flavonoids; Citrech recommends debittering on absorber resins for an optimal use. Hereinafter howliquid looks like before and after debittering and HPLC chromatograms of flavonoids before and after treatment: